EFFORTLESS IOT DATA INTEGRATION | ENHANCE CONNECTIVITY & DECISION-MAKING

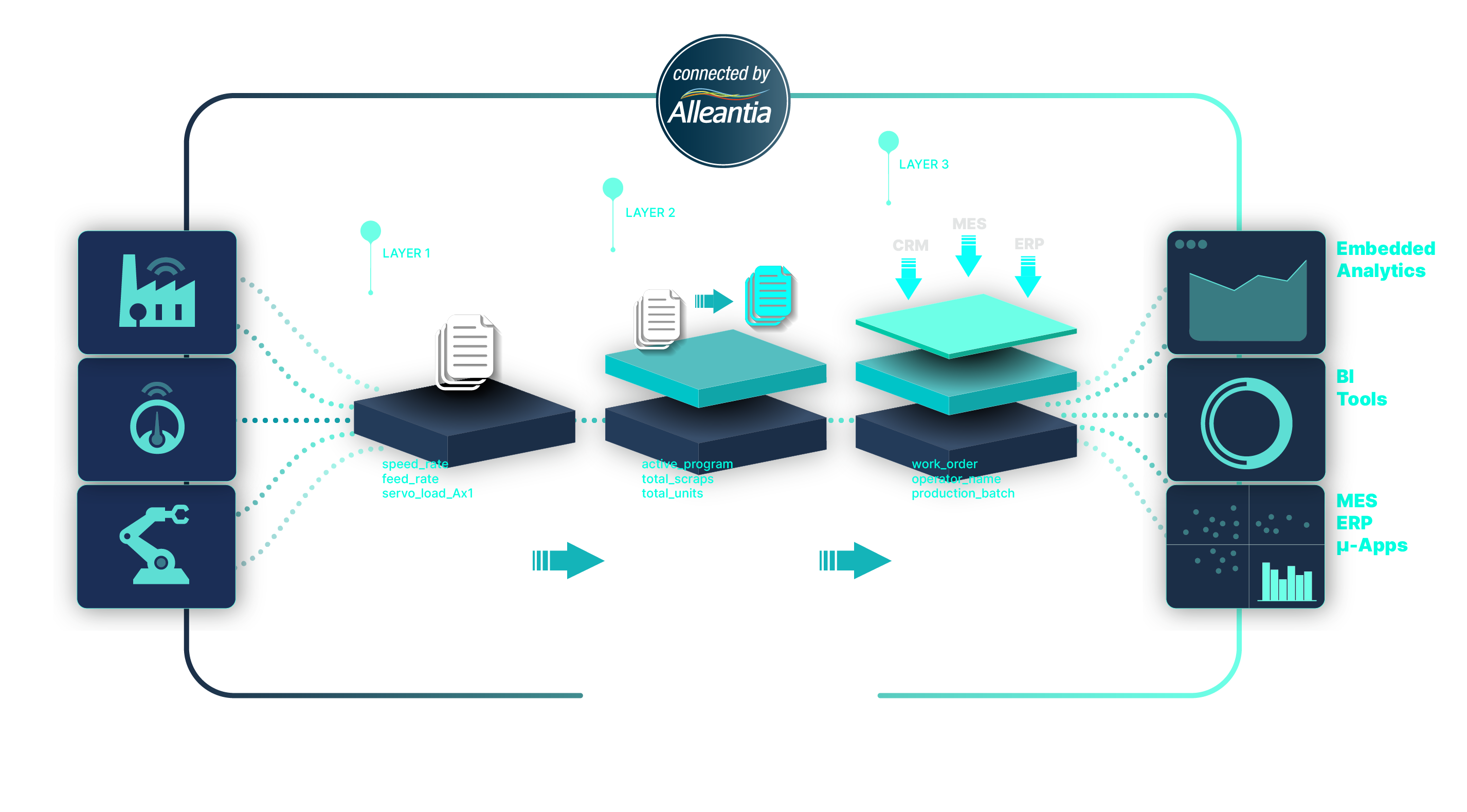

Extend machines data with context data.

Facilitates process and operation analysis.

DATA INTEGRATION

EFFORTLESS IOT DATA INTEGRATION

Facilitates process and operation analysis by correlating ‘zero coding’ machine data with application and operator data.

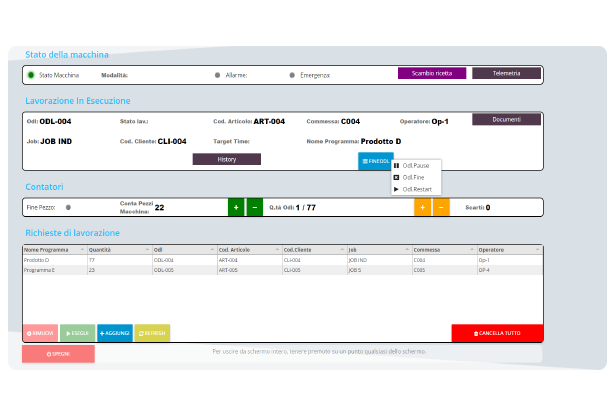

READY-TO-USE OPERATOR INTERFACE

More accurate, timely, and production data management

To make it easier for machine operators to handle manual data, an operator interface is available for displaying production data, and for manual data entry combined with machine data.

The operator interface can be used to enter any type of contextual data to the machine data not provided by applications (e.g., selection of the recipe to be run, stop causalities, etc.).

The operator interface software can be installed together with the IoT Edge Gateway software in ‘all-in-one’ hardware, thus optimizing cost and ICT architecture on the factory floor.

Alleantia – NewsRoom

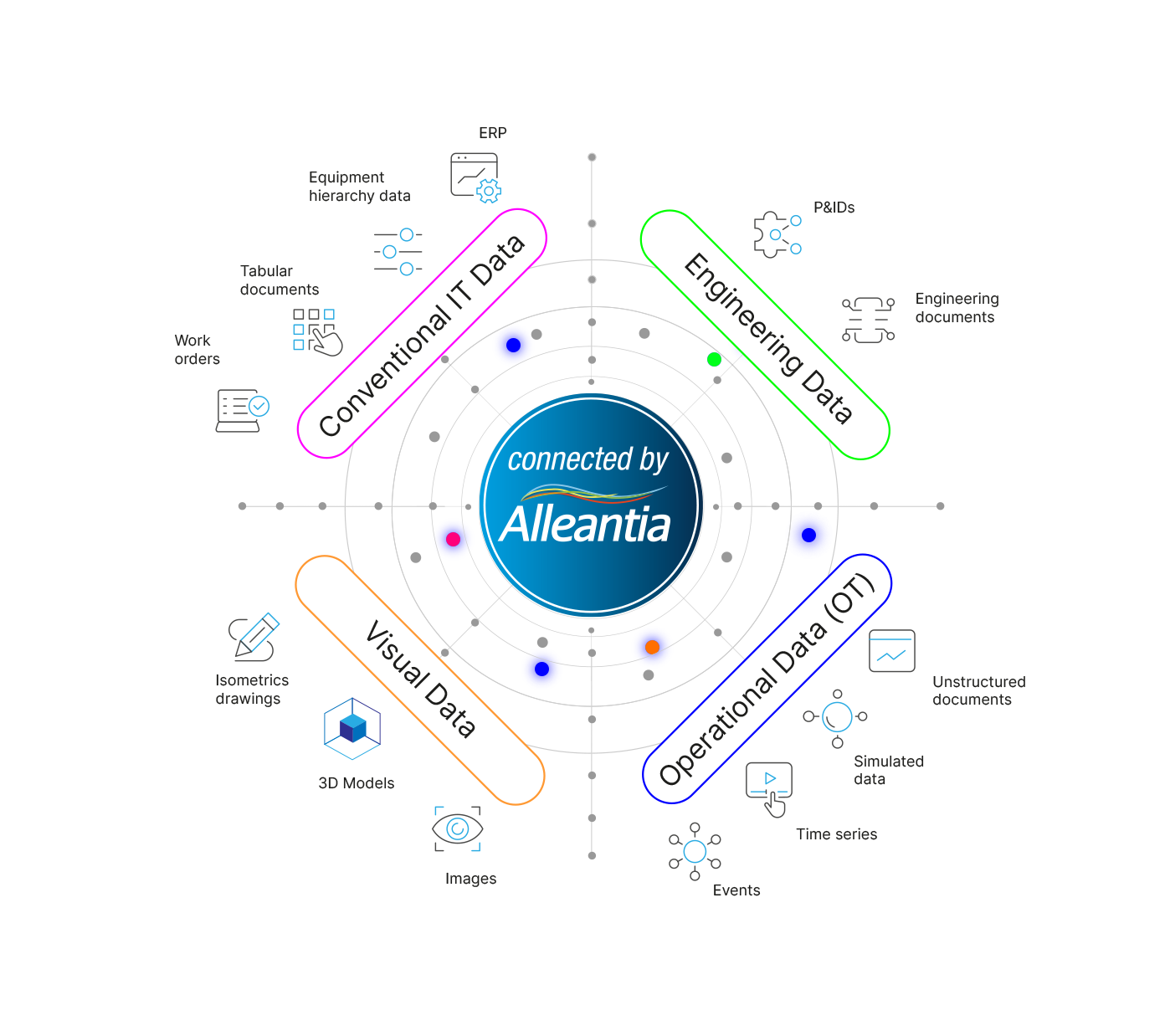

Data Integration – What are the benefits?

Unify machine data structures, combine machine data with other data sources in real time, create standardized data models.