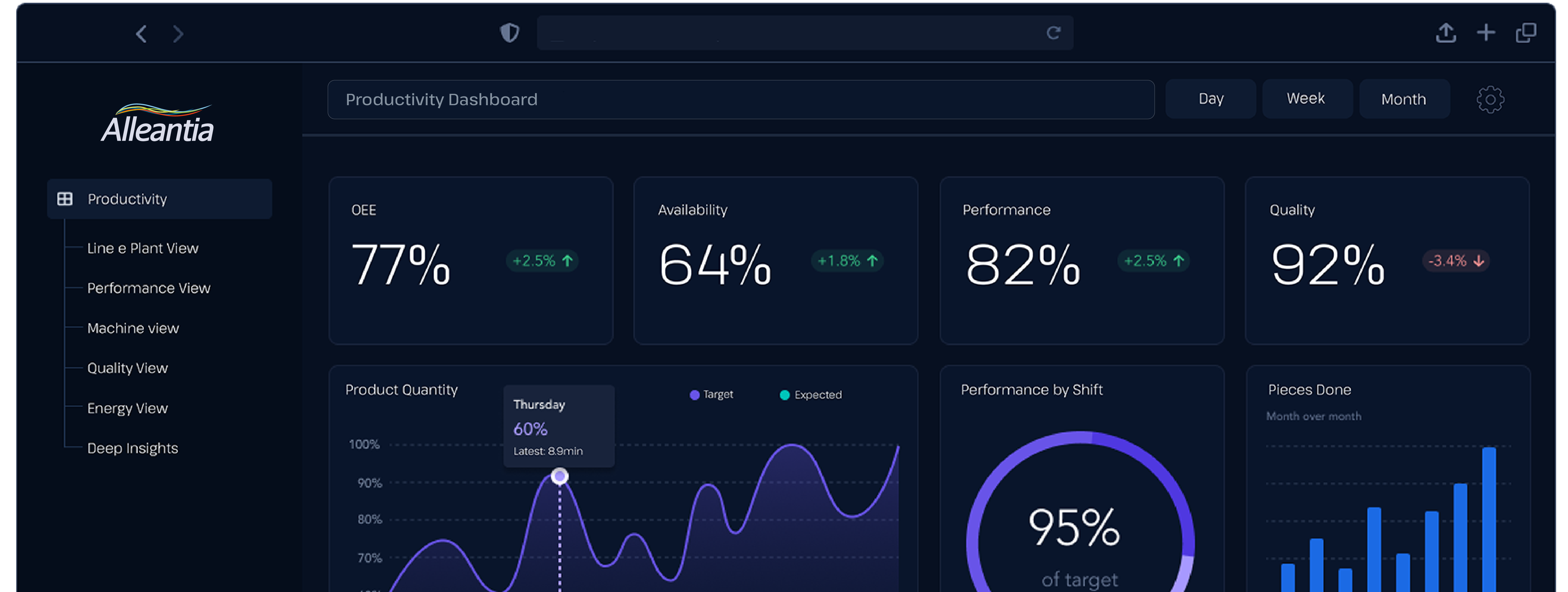

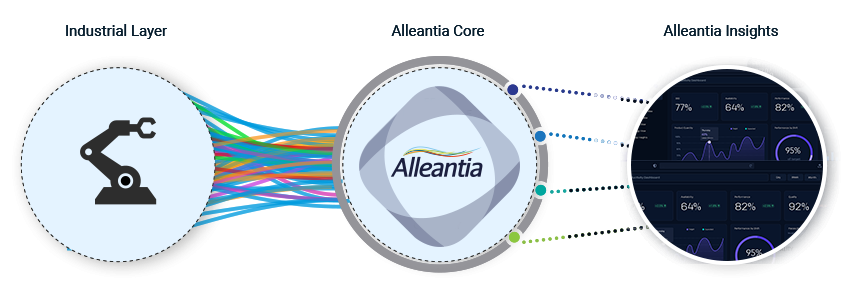

Start optimizing your machines performance in days through ready to use analysis, KPIs and visual dashboards.

Each insights provides one “View” for supporting specific, requirements, KPI calculation, with its and visualization dashboard.

A specific view dedicated to scraps analysis:

A specific view dedicated to energy usage analysis in production:

A specific view dedicated to CNC machine program performance and tools management